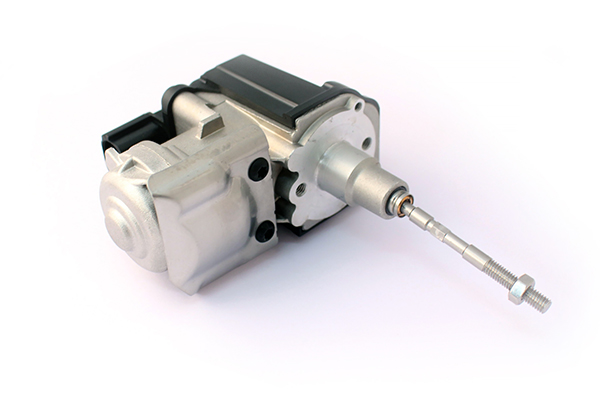

Turbochargers have revolutionised modern engine design, enhancing power and fuel efficiency by harnessing exhaust gases to drive compressed air into the combustion chamber. As a result, turbocharged systems are now commonplace in vehicles of all types, from light commercial vans to high-performance cars. But as Melett, a leading name in precision-engineered turbocharger components, stresses, correct installation is everything.

Melett, who supplies parts and repair solutions to the professional aftermarket worldwide, warns that improper turbocharger installation remains a leading cause of premature failure and engine damage.

“We see the same core mistakes repeated in the field,” says Melett’s technical team. “These aren’t just minor oversights; they’re errors that can lead to full unit failure, warranty claims, and reputational damage for workshops.”

Here, Melett explores the five most common installation errors, alongside expert advice on how to avoid them.

Improper Sealing of Joints

One of the most frequent and damaging errors involves sealing oil connections with silicone. While it might appear to offer a quick seal, silicone is wholly unsuitable for turbocharger applications. Small fragments can break loose and enter the oil system, where they may block vital passages and cause bearing seizure.

Melett strongly advises the use of high-quality, model-specific gasket kits. These ensure a proper seal without contaminating oil flow and help maintain long-term reliability. Gaskets must be perfectly aligned; any offset could restrict flow and create avoidable wear.

Failure to Remove Safety Caps

A surprisingly common oversight, particularly among less experienced technicians, is failing to remove protective shipping plugs before installation. These caps are there to protect the turbo during transport but will completely block oil flow if left in place.

Melett recommends a thorough visual inspection of all parts during pre-installation checks. This one simple step can prevent immediate and catastrophic turbo failure on first start-up.

Contaminants Left Behind from a Previous Failure

When a turbocharger fails, it often leaves behind debris—metal fragments, carbon deposits, or degraded oil—that can lurk in oil lines, intercoolers, and intake pipes. Fitting a new unit without properly flushing these systems is a fast track to a second failure.

Professional installation must include complete system cleaning and, where necessary, component replacement. Melett supports the use of specialist cleaning fluids designed to remove even microscopic contaminants, safeguarding the new turbo from the outset.

Neglecting the Oil System

The turbocharger relies entirely on a clean, reliable oil supply for cooling and lubrication. Poor oil maintenance, incorrect oil grades, or low oil pressure are all critical risk factors.

Before any installation, technicians must replace both the oil and the filter with OE-specified products. Melett also advises checking and clearing the oil feed and return lines and verifying oil pressure before the engine is restarted. This due diligence can prevent many avoidable call-backs.

Failing to Identify the Root Cause of Previous Failures

Installing a replacement turbo without diagnosing the root cause of the original failure is perhaps the most expensive and frustrating mistake. Underlying issues—ranging from faulty injectors and clogged filters to defective EGR valves or blocked DPFs—will rapidly destroy a new turbo if left unresolved.

Melett urges workshops to conduct comprehensive diagnostic assessments before fitting a new unit. This includes checking related engine systems that could indirectly affect turbo operation. Only by resolving these underlying faults can the technician ensure the long-term health of the new turbo.

A Professional Standard: Fitting for Reliability and Reputation

Each of these mistakes, while avoidable, can carry a heavy cost, not just in terms of parts and labour, but in reputation and customer trust. Melett emphasises that turbocharger fitting isn’t a routine replacement job, it’s a specialist task that demands care, cleanliness, and technical precision.

“We always encourage installers to think beyond the part itself,” says a Melett technical advisor. “Every turbo is part of a wider system. Getting it right protects the engine, safeguards your reputation, and keeps customers on the road.”

Melett’s commitment to technical support, quality components, and accurate fitment information underpins their approach to turbocharger repair and installation.

Because when it comes to turbochargers, precision isn’t optional — it’s essential.